Industry 4.0

Data becomes intelligence - increasing productivity, quality, and savings

The digitalisation of production processes forms the basis of the Fourth Industrial Revolution, which is also referred to as Industry 4.0. It involves the integration and control of entire supply chains with the aid of state-of-the-art information technologies that are facilitating completely new business models.

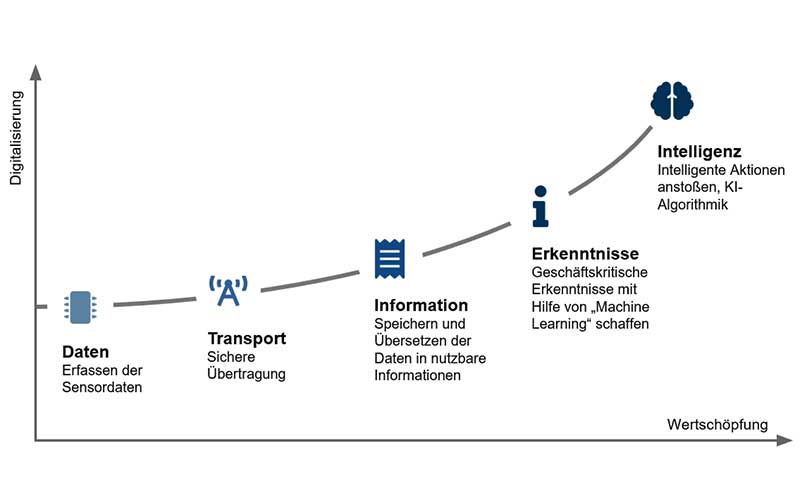

Adding value by digitalization

Contact Person

The advantages of Industry 4.0 are real:

- A strong increase in productivity has been confirmed by 60% of digital technology users in manufacturing. This is achieved by reducing unscheduled downtimes and improving machine availability.

- A cost reduction of up to 50% is feasible for the user. Real-time monitoring, anticipative maintenance planning, increased automation and energy efficiency make this possible.

- Real-time quality control methods helped 42% of the users to boost product quality thus reducing the number of products returned by customers.

Data as key element of Industry 4.0

The integration of data is essential to successfully implemented Industry 4.0 projects. The point is to compile the various types and formats of data from the corresponding systems and transform and prepare these for use by other programs such as Predictive Maintenance or Predictive Quality.

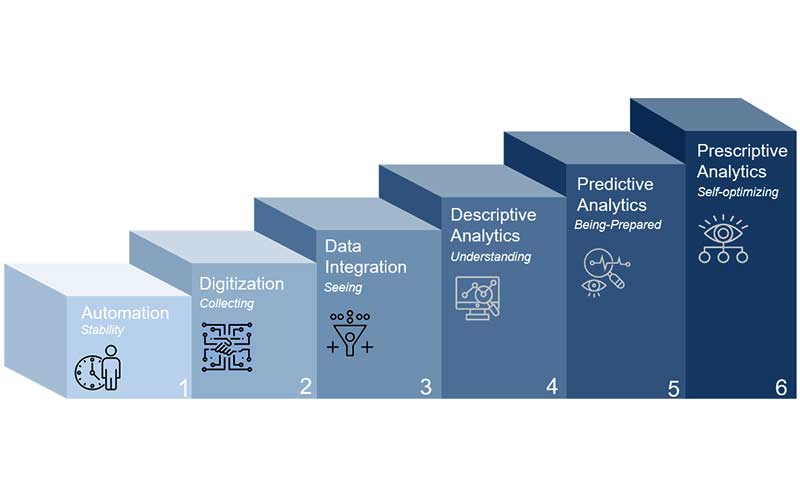

Steps on the road to a digital production process

Which step are you on?

This step involves the optimisation of production systems without the use of programmable logic controllers (PLCs).

Recommended measures:

- Installation of programmable logic controller

- Upgrade of electronic equipment (control cabinets, sensors, actuators)

- Modernisation of drive technology

Achieved optimisations:

- Automatic operation of production process

- Increase in production speed

- Establishment of reproducible processes with the aid of recipe management

- Quality improvement thanks to faster and more accurate control

- Effective procurement of spare parts and, therefore, fewer downtimes

Example of field application:

- Industry: Manufacturer of packaging

- Area: Optimisation of extrusion coating line

- Results:

- Productivity increased by 16%

- Waste/Rejects reduced by 40%

Here the focus is on optimising production lines equipped with PLCs without or with low capacity for data acquisition.

Recommended measures:

- Installation of sensors for the collection of data points such as temperature, pressure, energy consumption, material flow, warehouse management, etc.

- Importing of data required for production processes such as recipes, information on materials, etc.

- Ongoing data acquisition and data storage during production

Achieved optimisations:

- Potential for savings with the aid of collected energy consumption data

- Quality improvement thanks to faster and more accurate control

- Archiving of data in case of a potential complaint

- Quality monitoring (target/actual comparison)

- Monitoring of material flow and throughput rates

Example of field application:

- Industry: Automotive industry

- Area: Optimisation of a drying system

- Results:

- Energy consumption systematically reduced by 8%

- Rejected complaints verified based on recorded data

Rather than feeling daunted by digital technology companies should embrace and exploit the opportunities offered by Industry 4.0 to benefit from the many advantages. To this end, every organisation has to undergo a process of growth and development.

“Think big, start small” is good advice to begin with. When your focus is on a single component or a production line the relatively small and manageable project scope enables you to gain first-hand knowledge. The implementation processes and successful learning can be expedited for a company by consulting experts when needed.