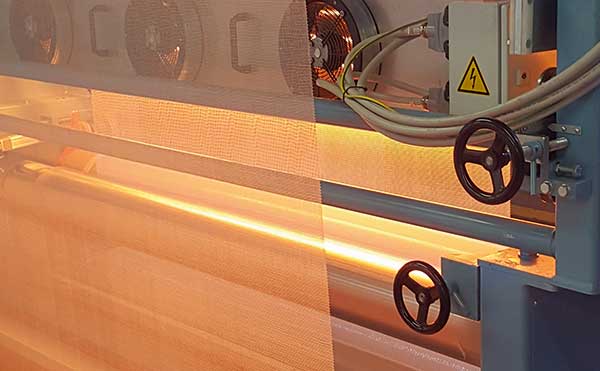

Customized Infrared Drying Technology Achieves Best Results and Highest Efficiency

As an engineering and service provider, MES offers comprehensive customer- and branch-specific system competency with process expertise in the area of IR drying technology.

MES infrared drying system solutions in the form of line radiators, area radiators or customized infrared dryers offer advantages in three areas: they boost the production output, reduce energy costs, and achieve a premium surface finish.

Contact Person

lnfrared radiators | lnfrared modules | lnfrared dryer

with rapid short- and medium-wave infrared radiation sources

production increase

faster heating | better drying | higher gloss level | more energy efficiency

Infrared heating and infrared drying

for coating and painting

excellently combinable with convection dryer

MES Infrared Drying Technology – Innovative Technical Concepts for the Optimum, Economical Solution for Your Thermal Processes

More than 50% of all manufacturing processes involve thermal processes

Our company guidelines reflect our commitment to provide our customers with optimum solutions for meeting their requirements, which is why we offer a comprehensive range of services in response to these thermal process requirements. The MES Infrared Drying Technology represents the range of products and services which reflect the variety and diversity of thermal applications.

MES Infrared Drying Technology ... more than heating systems

The MES Infrared Drying Technology stands for a wide range of products that form the basis for the highly flexible development of fully integrated, innovative concepts. We develop the optimum, economical solution for meeting the thermal process requirements by tapping into a pool of complementary expertise:

- Extensive experience in building custom machines

- Process engineering expertise

- Full service (from design to engineering of complex thermal processes, all the way to start-up)

- Professional consultation services

- Standardized components (lineIR line radiators and MES plainIR area radiators)

- Customized heating and/or drying systems

We deliver appropriate equipment for new production systems across all industrial sectors just as we provide customized additions to existing production lines or optimization measures of existing drying capacities including modernization, restoration, or upgrade services, or accessory equipment, etc.

Thermal processes: your problem is our task

Heating or drying system requirements are determined in most cases by the products and materials to be heated or the substrates to be dried in combination with the corresponding base materials (print or coating substrates).

We will work out problems and find appropriate solutions together with you. The selection of the most appropriate technology to handle the thermal task is at the heart of the solution.

Our comprehensive consultation and delivery services comprise:

- Variable material transport, i.e. transportation technology appropriate for the material using guide rollers, cooling rollers, conveyor belts, etc.

- Possibly required drive technology components and additional units

- Design and connection with existing machine controllers and visualization programs

- Systems for the energy supply, exhaust, circulating air, exhaust air purification, LEL gas warning systems, etc.

MES-Finishing Plants + Finishing Components

Everything to be dried has to be supplied or applied; and everything which is to be continuously dried is subject to further material flow processes in addition to thermal processes.

We offer a separate product range of machines and finishing components under the “MES Plants + Components” name, which can be effectively combined with MES Infrared Drying Technology.