MES solut IR – Combination Infrared/Convection Dryers: Perfectly Suitable for Challenging Fabric and Web Drying Processes

Combination infrared and convection dryers offer the optimum drying method especially if difficult-to-dry media are applied to fabrics or webs. Examples of requirements include:

- Rapid activation of adhesive film

- Cross-linking of polymer mixtures

- Fixation of paint

Contact Person

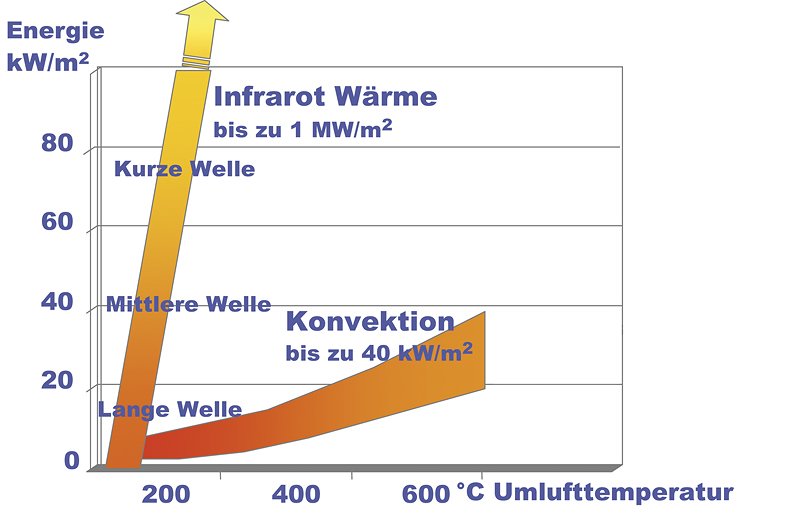

The scope of applications comprises a variety of drying processes for woven and non-woven fabrics, plastics webs, and paper. The combination of infrared and convection heat is impressive in three ways:

- Excellent product quality: uniform drying, free from blisters

- High process speeds: high drying speeds due to maximum possible heat transfer rates

- Energy efficiency: effective utilization of energy for economical drying processes

Design Dimensions

- Customized web width solutions from 1,200-6,000 mm

Application Areas

Characteristics

Available Options

Technical Data

- Textile industry

- Flexible packaging

- Print media

- Paper industry

- Wallpaper manufacture/Decorative printing

- Superior drying speeds

- Short drying distances

- Infinitely variable control of infrared radiators

- Reflectors for full energy exploitation

- High air circulation rates for perfect temperature control

- Convection current for perfect load discharge

- Available with explosion protected equipment

| Temperature range: | 80–300 °C |

| Air circulation rate: | Up to 26,000 m³/h |

| Infrared radiation: | Short-wave or medium-wave |

| Length of drying range: | 3,000 mm |

| Installed load: | Process-specific |

Thomas Steinwachs

Head of Service