MES solutIR – High-Performance Drying Systems for Fabrics and Webs – Individually Designed

Demands for higher drying speeds with consistently high or improved quality continue to grow. MES thermsol® drying systems combine infrared technology with convection drying technology in an extremely efficient manner so as to achieve optimum production results.

Do you finish, coat, print or paint products and you aim to increase your production rate while meeting a high quality standard?

We develop the drying system or combination of drying systems appropriate for your individual processes complete with the matching material transport system.

Design Dimensions of MES solut IR Drying Systems

Customized working width from 1,200 to 6,000 mm.

Contact Person

Efficient drying of threads and webs; all components have been adapted to the corresponding drying process in the following areas:

- Printing

- Painting

- Finishing

- Coating

MES solut IR drying systems are suitable for use with water-based or solvent-based dispersion agents.

Infrared: Quick to respond IR elements enable a quick heat-up time and prevent heat damage to the material during a line stop.

- High output density, achieving:

- Rapid, effective drying action

- Short drying distances

- Individually variable infrared radiator output control units

Convection: The air circulation ensures an even temperature distribution.

- Generous quantities of circulating air

- Frequency-controlled exhaust volume flow rates

- The integrated humidistat in the flow of extracted air ensures an effective and energy efficient drying process.

- Explosion protected equipment for solvents

| Dryer width: | 1,200-6,000 mm |

| Drying speed: | 5-200 m/min |

| Drying type: | Infrared radiation in combination with convection air circulation as needed |

| Radiation type: | Short-wave or medium-wave infrared radiation |

| Dryer design: | Vertical or horizontal continuous flow dryer |

Customized Continuous Flow Dryers with Drying Ducts for Yarns and Threads

Design and dimensioning specifications for continuous flow dryers for yarns and threads are subject to special criteria such as, eg:

The individual filaments are positioned close to one another and indicate a specified slag. This influences the flow of air in the drying duct. Cavities will be formed between the spaces of the filaments, which likewise will be filled with coating media. This results in different solvent diffusion rates.

MES accounts for a variety of criteria like this in the design of continuous flow dryers for yarns and threads to customer specifications eg with respect to the annual production goal.

Continuous Flow Dryer with Transverse Airflow to Threadsheet

- Hot airflow in transverse direction to threadline

- Higher heat transfer rates due to high inflow velocity Turbulent flow

- The airflow carries the thread - low thread tension is possible

- Solvent loads can only be controlled if built in segments; otherwise, time-consuming start-up and adjustment procedures for taking measurements

Textile industry:

- Drying of thread and yarn coatings

- Superior drying speeds

- Short drying distances

- Infinitely variable control of infrared radiators

- Reflectors for full energy exploitation

- High air circulation rates for perfect temperature control

- Available with explosion protected equipment

| Temperature range: | 80-260 ° C |

| Air circulation rate: | Up to 26,000 m³ / h |

| Infrared radiation: | Medium wave |

| Length of drying range: | 3,000 mm |

| Installed load: | Process-specific |

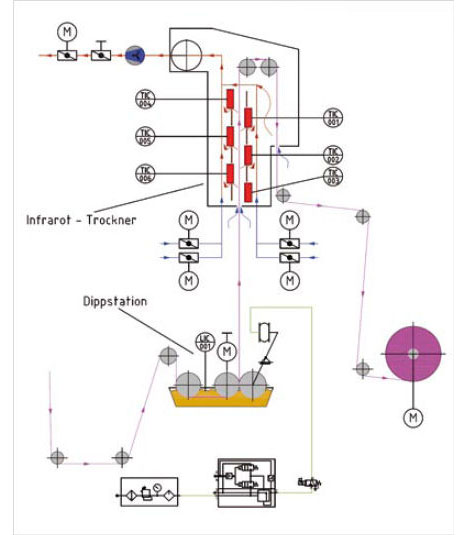

MES Filament Thread Dryer

In the summer of 2011, MES GmbH has started up the operation of two drying plants for the drying of filament threads specifically developed for customer requirements for the drying process of functionalized filament threads .

The dryers projected for the use of solvents are operated with an indirect gas heating in a safe and economic way . A particular compactness has been achieved through nine passages in the dryer room.

Sliding doors have been installed for the access to the internal deflecting rollers in the area of the thread inlet and outlet for a fast and effective set-up of the dryer.

- Explosion protection design

- Horizontal thread passage

- Vertical cross-flow air guiding with air nozzles

- Large circulation air volume flows for an effective drying process

- Easy-operation high-temperature bearing with dry lubricating agent I maintenance-free

- Control system with tough panel and 5 graphics for an intuitive operation

- Safety-directed control: Performance level "d"

| Number of threads: | 80 (filament threads) |

| Number of passages: | 9 |

| Evaporation performance: | 150 kW |

| Medium: | Dissolvent, water |

| Temperature: | 100-250 ° C |

| Circulating air volume flow: | Frequency-controlled |

| Exhaust air volume flow: | Frequency-controlled |

| Overall dimensions: | 5060 mm x 3400 mm x 2650 mm |

Thomas Steinwachs

Head of Service