MES Pilot Installations for Web or Fabric Finishing Processes and for Continuous Product Improvement

With your range of products you are one of the leaders in the textile and plastics markets. You win over customers by your product quality and your company has to defend its excellent reputation. The market, however, demands new and optimized products at ever shorter cycles.

You need effective and economic product development to maintain your market position.

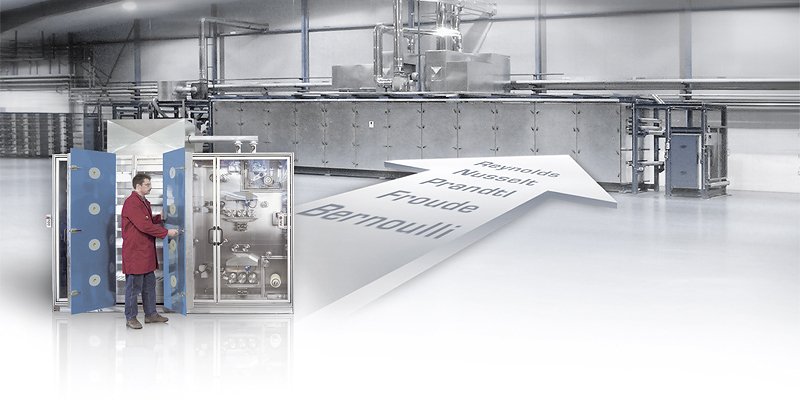

With pilot installations from MES you will achieve development results, which can be transferred to your production process on a 1:1 scale – at rapid development cycles.

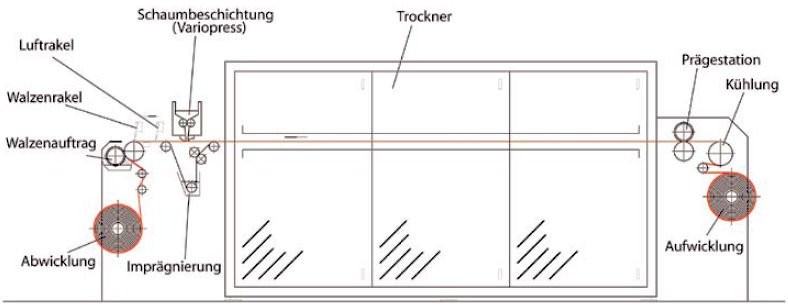

Project example: Laboratory fabric coating system

Laboratory coating systems facilitate the development of coatings with foams, pastes and liquid coating media. Various application stations and a wide speed range enable reproducible development results of new products and processes. These systems feature a modular design and individual components can be replaced.

Due to their compact design, these machines are also perfectly suited for the manufacture of small batches while ensuring economic efficiency.

Contact Person

Textile industry, plastics industry, decorative printing industry

- Development of new textile finishing products and methods (fabrics and webs)

- Development of new finishing recipes

- Manufacture of sample production batches and small batches

- Development of fabric coatings with foams, pastes and liquid coating media

- Precision adjustable roller coating systems

- Components: unwinder, coating units, circulating dryer, winder, controller

- Various application methods: roller doctor blade, air doctor blade, knife-on-blanket coater, kiss coater, roller coating, diffuse coating

- Suitable for use with solvents

- Chromed roller surfaces

- Stainless coating troughs

- Driven by three-phase geared motors

- Complete automation and visualization

- Process data management system

- Impregnation padder and embossing station can be integrated

- Explosion protected design available

| Web width: | 300-500 mm |

| Speed: | 1-30 m/min |

| Application amount: | 5-200 g/m² |

| Temperature range: | 80-260 °C |

MES Pilot Installations for Reproducible Development Results

With MES pilot installations your can develop new products and test product variants independently of the current production. Our installations can be used in many ways; they are in line with state of the art technology and work like a model of the actual production line. You can record and evaluate test results. In this way you can obtain conclusive data for reproducible new products.

MES pilot installations give you a leading edge over your competitors

- Effective, economical development

- Reproducible development results

- Parameter reliability for transfer to production conditions

- Rapid product realization on production line after testing

- Continuous product improvement

- Rapid development times

- Quick set-up times

Physical layout of MES pilot installations

- Dryer chamber and nozzle geometry adapted to similarity theory

- Large circulating air flow; exact calculation of air nozzle width

- Dimensionless quantities: data can be compared with production lines

- Variable due to cutting-edge control technology for the advancement of products and systems technology (frequency converter for fans)

- Impregnation and coating stations with dipping displacement adaptation regarding coating application speed and geometry

- Variable due to replaceable units

- IT-supported evaluation of test data and data recording

Our services at a glance

- Development and planning of pilot installations (PIs) for yarns, threads, fabrics and web-shaped materials

- Construction of pilot installations in accordance with customer requirements and based on similarity theory and non-dimensional parameters

- Supply of PIs with

- exchangeable units which allow the process variability to be extended

- impregnation and coating stations with flexible immersion-depth adaptation

- drying rooms and nozzle geometry developed according to similarity theory

- modular structure to allow for additions to drying zones

- suitable solvents and equipment suitable for explosive atmospheres

- variable product guide, even for winding and unwinding

- process visualization and language switching

- Modernization of pilot installations

- Procedural and engineering services

Thomas Steinwachs

Head of Service