Versatile MES Pilot Installations for Yarn and Thread Treatment and Economical Product Development

You want to optimize the process parameters of modern production systems or develop new yarn or thread products. MES offers variable, modular pilot installations specially designed for the production of yarns and threads. These pilot installations are based on the extensive process expertise we have acquired from working in the textile industry, so that any conceivable production tests can be carried out. Distinguishing characteristics include:

- Variable thread guide

- Exchangeable application systems

- Variable drying system (infrared and/or convection)

- Wide temperature ranges

- Many variants for winding and unwinding systems

- Continuous recording of data with graphic and statistical analysis

Extensive design options and low investment costs

The large selection of individual performance characteristics provides extensive design options. MES pilot installations for yarn and thread production incur low investment costs because they are custom designed to meet your requirements. Furthermore, low maintenance and ease of expandability keep operating costs reasonable.

Contact Person

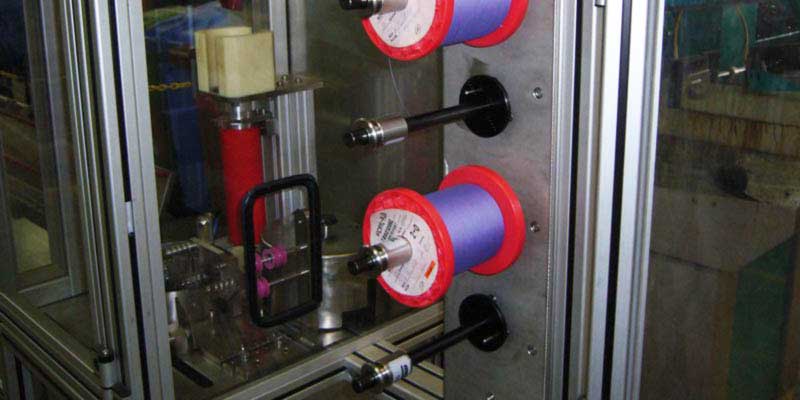

Project example: Compact Pilot Installation for Thread and Yarn Treatment

As early as fall 2003, MES GmbH had plans for an up to then not realized compact unit of a pilot installation for thread and yarn treatment. The installation is modular, expandable and offers the following advantages:

- Comprehensive thread treatment in one process step

- Variable thread guide for different process steps

- Compact dimensions permit production of small test samples

- Preselectable control of tension and synchronized degree of drawing

- Easy to operate intuitive user interface of visualized control

- Evaluation of test results of documented process quantities; easy to view graphic format

- Extensive diagnostics options

- Modern, low-maintenance technology

- Effective and economical development of new thread and yarn products

- Short development lead times for product innovation and product improvement

- Cost-effective manufacture of small sample quantities independently of the current production

- Development of new finishing recipes

- Explosion protected design for operation with solvents

- Products: Single cord, twisted yarn, yarns, synthetic monofilaments

- Speed from 0.2 to 15 m/min

- 4 separate thread drawing zones

- 6 thread tension measurement sensors

- 3 dip application stations with doctor blades and exhaust system

- 2 temperature-controlled drying ducts

- 2 temperature-controlled polymerization tunnels

- Visualized control with data documentation

Thread development machinery of MES – Similar-coat systems for yarns, threads and cords

The MES similar-coat system will even fulfil the highest requirements for a thread development plant:

- Extremely large range of upgrading and coating options (dipping, immersion, coating etc.)

- Transferability of the coating processes onto your production plant without negative scale-up effects

- Extremely large range of speeds exceeding the requirements of the production plant

- Extremely large temperature ranges with highly accurate temperature distribution (± 3 °C) and controlled default values.

- Ability for sampling, zero series, step-by-step testing, small series

- Complete quality monitoring with defined reproducible tolerance dimensions

Similar models, where you will be able to transfer the development results 1:1 to your production plants

- For the coating and upgrading results

- For the process engineering finishing and process parameters

The state-of-the-art technology enables the flexible adaptation of the operating parameters.

If you need a development machinery reproducing your production machinery 1:1 in the development machinery scale, we recommend to you our fully-automatic MES similar-coat systems.

Similar-coat system for the finishing and dipping of single cords, for example

Thomas Steinwachs

Head of Service