Comprehensive Factory Planning – “Start of Production” On Schedule and at a Fixed Price

You are planning to build a new factory complete with machines for finishing, printing, laminating, or painting applications? For meeting your requirements you will need an experienced service provider in the field of plant engineering, with expertise in the area of the plastics, packaging, or textile industry.

MES will plan your new factory and assume full responsibility for organizational and technical matters. We provide comprehensive factory planning services; you will have only one contact person for all business areas. You will be protected against damage by extensive liability insurance coverage.

On this basis we guarantee cost-effective factory planning at a fixed price and on schedule.

And only on this basis can the successful production line set-up and start of production follow – also carried out by MES with comprehensive services worldwide.

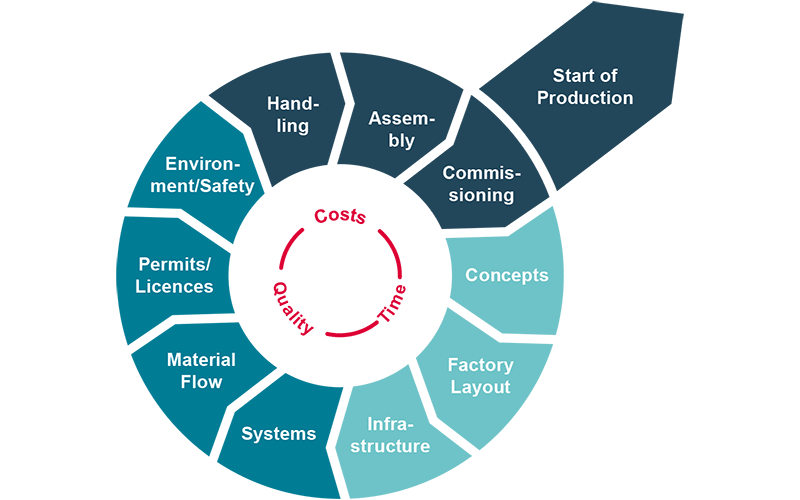

Successful factory planning with MES

The experienced MES team takes into account a large number of factors during project preparations. Our comprehensive planning activities reach beyond interfaces and assure you of the greatest possible planning security.

- Planning of activities

- Scheduling

- Interface coordination

- Communication (internally and externally, with authorities, etc.)

- Cost management

- Human resource planning/Resource planning

- Infrastructure/Operating technology (energy supply, water, air, refrigeration, exhaust, climate control, etc.)

- Infrastructure/Associated areas (storage facilities, laboratory, servicing, etc.)

- Material flow planning

- Installation plan, production lines

- Fire protection/Occupational safety and health regulations/Environmental protection regulations

- Technical inspections/Training

- Start-up/Start of production

- Resources:

- Skilled labor

- Operating equipment

- Supply systems

- Permits

- Documentation

- Drawings

- Circuit diagrams

Our planning accounts for critical time factors:

- Permits with approval documents

Planning in case of moving or modernization of a production line

Moving your production lines opens up new opportunities and synergies. Maintain or boost the performance, quality and productivity with measures related to the:

- Need for modernization

- Optimization of material flow

- Optimization of the infrastructure

- Occupational safety and health regulations

MES will plan the risk-free relocation of your production lines. We achieve this goal by:

- Production line photos

- Machine identification pursuant to DIN ISO 16952

- Packaging appropriate to the type of product to be transported and the type of transportation

- Logistics

Careful planning leads to only brief production downtimes even if certain measures need to be taken at the site.

- Restructuring of factory/Restructuring of production line

- Modernization of production

- Revision of machines

Textile industry, packaging industry, plastics manufacturing industry, paper industry, auto industry:

- Drying machines

- Finishing machines

- Printing machines

- Laminating machines

- Painting machines

- Presses

- Silos and mixing machines

- Exhaust systems

We take care of the entire infrastructure for your production line including planning and obtaining permits or licenses.

- Waste water

- Operating equipment

- Energy systems

- Materials handling equipment

- Climate control

- Warehousing

- Environmental protection

Thomas Steinwachs

Head of Service