Maintenance for the industry - Long-term maintenance targets will support production targets

MES is specialized in varnishing-, lamination-, printing- and finishing machinery in plastics-, packaging- and textile industry. The maintenance for these sectors of industry with a comprehensive, long-term approach is part of our core competences.

Are these requirements for maintenance sufficient for you?

- Higher degree of plant reliability

- Increased safety

- Improved product quality

- Prolonged service life of plant

- Higher profitability

Or do you want to organize your maintenance even more profitable on the long run with:

- Environmental and quality management

- Energy saving program

- Adherence to delivery dates

- Risk assessment

- Spare parts logistics

Choose the second option and avoid maintenance costs as well as missed sales proceeds. Long-term maintenance targets will support the production targets!

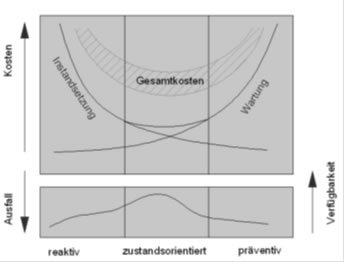

The optimum point of a maintenance strategy:

Orientation to total costs

The continuous and consequent collection and analysis of data will result in a medium- and long-term benefit by way of key figures in maintenance.

- Snapshots will excessively focus on the sole cost factor.

- The target must be the safeguarding of the total cost minimum in maintenance.

It is only possible to prove and further develop the value of the maintenance strategy chosen on the basis of key figures

How cost-intensive and cost-optimized the maintenance strategy chosen is, can only be reliably analysed and controlled through the introduction of the correct key figures.

If key figures are selected carefully, these will make the company structures, processes and company development transparent.

In accordance with VDI 2893, key figures are thus an indispensable component of a maintenance process. In the field, however, a set of 16 parameters is fully sufficient as a range of key figures!

The Balanced Score Card Model (BSC) can be used to generate the key figures enabling the multi-dimensional measurement of the overall maintenance performance.

Key figures can be used in maintenance for the following purposes:

- Strategy planning

- Budget planning and organization

- Comparison of plants and facilities

- Evidence for the efficiency of measures planned and implemented

The optimum maintenance strategy will always be subject to changing frame conditions:

The optimum maintenance strategy will always be positioned in the area of tension in practical operation between:

- Too much or too little maintenance

- Between costs and benefits

- Between risky and safe operations

We recommend a product-oriented maintenance, because this way the maintenance targets will support your production targets!

Thomas Steinwachs

Head of Service