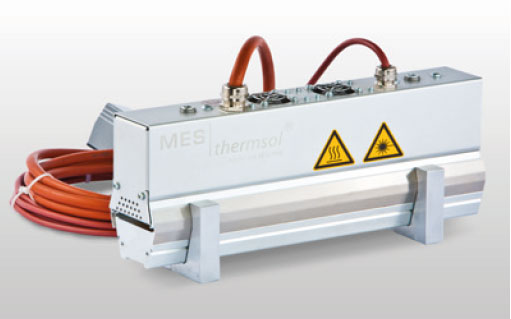

MES tubeIR CP / CF infrared tube radiators for efficiently heating and drying threads, yarn, wires, and similar round or bar-shaped materials

MES tubeIR radiators are perfectly suited for in-process heating or drying of fibrous or wire-like materials.

Contact Person

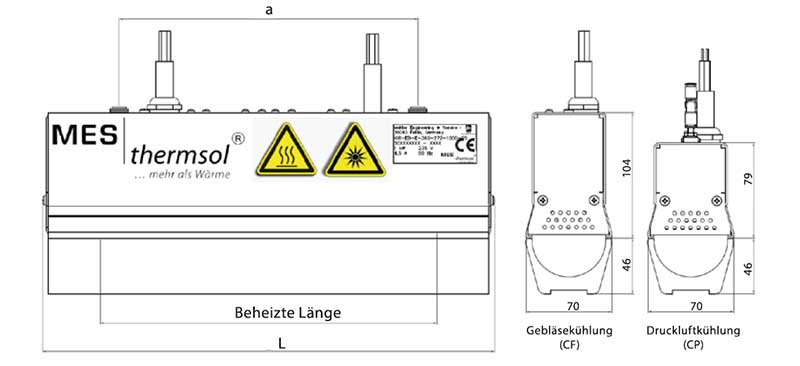

MES tubeIR Radiator Sizes

| Type of Reflector | Length L [mm] | Fastening a [mm] | Heated Length [mm] | Power [W] | Voltage [V] |

| tubeIR 230 | 232 | 150 | 140 | 500 | 110 |

| tubeIR 230 | 232 | 150 | 140 | 1.000 | 230 |

| tubeIR 360 | 369 | 244 | 280 | 1.000 | 230 |

| tubeIR 360 | 369 | 244 | 280 | 2.000 | 230 |

| tubeIR 360 | 369 | 244 | 280 | 3.000 | 230 |

| tubeIR 500 | 509 | 306 | 410 | 1.000 | 400 |

| tubeIR 500 | 509 | 306 | 410 | 2.000 | 400 |

| tubeIR 650 | 659 | 525 | 560 | 1.000 | 400 |

| tubeIR 650 | 659 | 525 | 560 | 2.000 | 400 |

| tubeIR 790 | 799 | 600 | 700 | 2.000 | 400 |

| tubeIR 790 | 799 | 600 | 700 | 3.000 | 400 |

Further unit types, designs, dimensions, power and voltage ratings are available. More information is available on request.

The following environmental conditions must be met for fan cooling:

- Room temperature < 30 °C

- Dust-free air

A significant increase in productivity, quality, and energy efficiency can be achieved when compared to non-enclosed infrared radiator elements, either by focusing the infrared radiators in the counter-reflector or through homogeneous tube radiation of the fibrous or wire-like material.

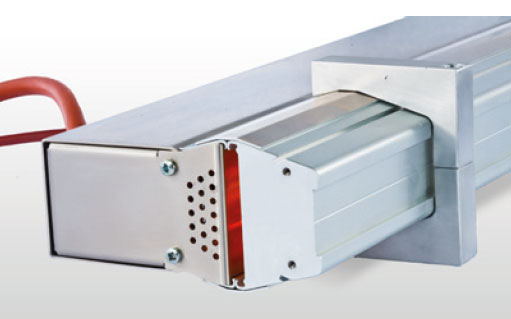

The modular design with a liftable upper section of the radiator unit, or even several units in succession, ensures that the product to be heated can be easily drawn in.

For drying purposes, the radiation source can be separated from the counter-reflector by means of a quartz glass pane so as to create a drying zone in the counter-reflector. Hot or cold air can flow through this zone so that produced vapors can be directly extracted and to optimally enhance the drying process.

- Heating and drying of functionalized yarns, threads, ropes, ribbons

- Wire heating

- Activation of bonding agents, varnishes etc. on round material

- Rubber, textile, plastic, medicine, industry

- Highly efficient heating through focussed infrared radiation in tube channel

- Heating from all sides through reflection foils

- Efficient use of energy through closed system

- Cooling with pressure or fan

- Radiation-relevant components can be replaced, thus completely technically revisable

- Can be used for short-, medium- and long wave radiation sources

- Quartz glass pane to separate the two chambers

- Integrated fans to supply cool air

- Airflow through counter-reflector for an optimum drying process

- Individual connection cable

- Individual fastening options

- In combination with convection drying

MES tubeIR Hybrid-Infrared Radiation Unit for efficient heating up of thread-like material

MES thermsol® tubeIR Hybrid-Radiation Modules are excellently suitable as tube radiators to heat up and dry thread-like or wire-like materials in a continuous throughput.

In contrast to standard infrared radiators, the infrared radiation will be focussed in the counter reflector and will generate a concentrated input of thermal energy.

Due to the concentrated energy input and the additional convective drying line, this type of radiators is highly efficient.

The convective drying line allows a direct exhaust of the vapours generated.

Sizes of MES tubeIR Hybrid Radiators

| Type of Reflector | Length L [mm] | Fastening a [mm] | Heated Length [mm] | Power [W] | Voltage [V] |

| tubeIR 720 | 729 | 604 | 1 x 272 | 1 x 1.000 | 220—250 |

| tubeIR 720 | 729 | 604 | 1 x 280 | 1 x 2.000 | 220—250 |

| tubeIR 720 | 729 | 604 | 1 x 280 | 1 x 3.000 | 220—250 |

Further unit types, designs, dimensions, power and voltage ratings are available. More information is available upon request.

The following environmental conditions must be met for fan cooling:

- Room temperature < 30 °C

- Dust-free air

- Highly efficient heating through focussed infrared radiation

- Increase of dryer output through hybrid technology

- Radiation-relevant components can be replaced, thus completely technically revisable

- Quartz glass panel to separate both chambers

- Individual connection cable

- Customized mounting options

| Radiation range: | Short-wave to medium-wave |

| Power: | 1,0–3,0 kW |

| Voltage: | 230 V / 400 V |

| Heated length: | 272–280 mm |

| Cooling: | Fan |

Thomas Steinwachs

Head of Service