MES is your partner for a comprehensive plant modernization

Only if you will consider all aspects of your production plant, you will reach the most economic solution in case of a planned plant modernization. As a comprehensive service provider, MES has all necessary competences in the field of electrics, mechanics, process engineering and automation - in the field of engineering as well implementation. MES is specialized worldwide in the field of varnishing-, laminating-, printing- and finishing machinery.

Reasons for the modernization of plants

- The maintenance costs of a production plant will increase in the course of the service life of the plant!

- The production quantity and quality will slowly (imperceptibly) decrease.

- The modernization of plants is an economic alternative to the new construction of production facilities, in particular at cost-intensive production locations and/or in low-margin markets.

- The basic substance of the production facility is excellent, at least in the mechanical section and of the components and equipment.

- Even partial modernizations, e.g. in the field of automation, will result in large-scale economic benefits.

- Safety and environmental conditions will force the modernization despite grandfathering.

- Facilities will be relocated (inside the plant or into other plants).

- Plant parts, spare parts for maintenance cannot be procured any more (this is mostly the case in the field of electrical systems and automation).

The feasibility study also includes: The plant modernization will always result in a value increase of the production facility!

Your Contact Person

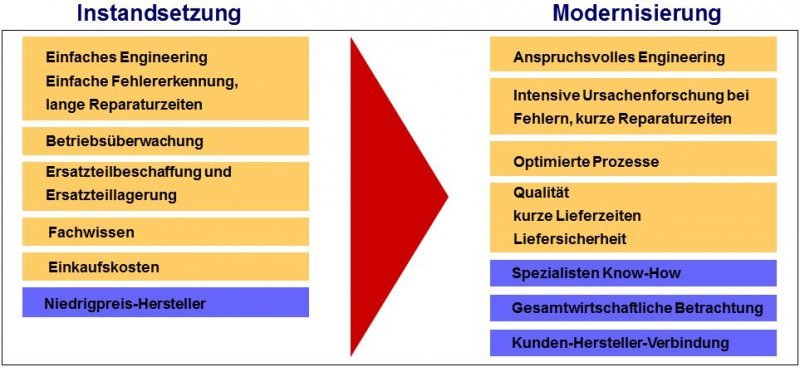

The modernization of a plant is a sophisticated engineering and service task

- The modernization of a plant is more sophisticated than a new construction of a plant.

- All project steps are required as for a new construction of a plant, but within shorter time periods, when using the existing substance, when considering all interfaces, with a high requirement for the quality of the production start.

- The competence depth of the performing company must also be Comprehensive even in case of a partial modernization.

- Engineering, manufacturing, delivery, installation, commissioning and optimization must be carried out with an own team of engineers and field-experienced staff members.

- All technical competences must be available (mechanics, process engineering, electrical engineering, automation).

MES is strongly positioned in all fields, so that you will be able to exploit all potentials of your planned plant modernization through a professional planning.

Plant analysis - The basis for a decision for modernization:

The decision for a plant modernization (or also for a new facility) can only be made on the basis of a profound knowledge and consideration of all technical facts, costs and future production targets.

The plant analysis required for this purpose can only be prepared with a team of specialists (process engineering, mechanical engineering, electrical engineering, automation).

The plant analysis will be carried out in two stages:

- Assessment of the process engineering and technical situation of the plant

- Collection of data and assessment of the mechanical situation of the plant

- Collection of data and assessment of the electrical engineering situation of the plant

- Collection of data and assessment of the degree of automation and of the quality of automation

- Performance of a hazard analysis

- Definition of the modernization targets

- Definition of the modernization measures

- Analysis report

- Decision on the partial steps of modernization

- Determination of costs

- Determination of the modernization periods

- Assessment of the economic efficiency

- Consideration of short-term and long-term production targets

- Consideration of alternatives, e.g. new construction of plant, second-hand plants, relocation

- Project recommendation

A comprehensive analysis of the plant will present transparency for you offering various different options. You will get all facts to make a qualified decision. This will guarantee to you the highest degree of security of investments.

Thomas Steinwachs

Head of Service